โปรแกรมการจำลองการเคลื่อนที่เม็ดอนุภาคในระบบชองแข็ง-ก๊าซ

Simulation Program for Particle Movement

in Solid-Gas Systems

ดร. สุนันท์

ลิ้มตระกูล

ABSTRACT

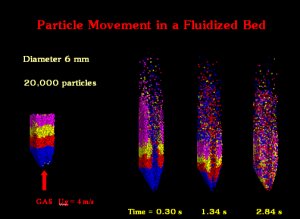

Gas-solid

systems such as pneumatic conveying and

fluidized bed play important roles in

industrial processes. Although, the solids

flow pattern in gas-solid systems is necessary

for the design and operation, it is difficult

to access due to the complex interaction

of the particles in the system. The two-fluid

model, which regards the solids particles

as a continuum was usually used to simulate

the flow behavior in gas-solid systems.

However, the great number of large particles

in the gas-solid systems requires the

model based on realistic assumptions such

as the Distinct Element Method (DEM) (Cundall

& Stract, 1979). This work aims to

develop simulation programs for prediction

the particle movement in various types

of solid-gas systems. Pneumatic conveying

system, gas-solid fluidized bed and vibrating

fluidized bed were studied. In addition,

the information regarding the solid and

gas flow patterns were used to incorporate

to the energy and mass balances to investigate

the heat and mass transfer in a fluidized

reactor. The program can predict the trajectories

of individual particles and the fluid

flow patterns. The motion of individual

particles was tracked by the solution

of the Newton's second law of motion.

The force acting on each particle consists

of the contact force between particles

and the force exerted by the surrounding

fluid. The contact force is modeled by

using the analogy of spring, dash-pot

and friction slider. The flow field of

gas was predicted by the Navier-Stokes

equation. The program was successfully

used to observe the flow pattern of plug

flow of particles in a horizontal pipe.

The critical superficial air velocity

for maintaining the plug flow regime was

obtained. The flow patterns, heat and

mass transfer in cylindrical fluidized

reactor were also calculated by the program.

The solids motion, mixing, temperature

and chemical conversion were found non-uniform

in the bed. The solids distribution is

very diluted near the center but high

near the wall. The temperature and chemical

conversion is also low near the center

but high near the wall. The simulation

result shows that the vibrated fluidized

bed can improve the poor fluidization

in the fluidized bed containing cohesive

particles. Furthermore, the program can

be also implemented to the particle flow

without fluid flow. Particle loading in

a large system cannot be done easily due

to the non-homogeneity of the particle

distribution. The proper design of the

loading system is important. The program

can monitor the particle movement in the

designed system.

|